19marcanthony99@gmail.com

Education

Cal State Northridge- Northridge, CA

- B.S. Mechanical Engineering: Expected Graduation (Dec. 2025)

SolidWorks Projects

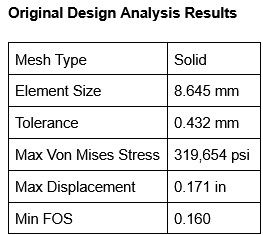

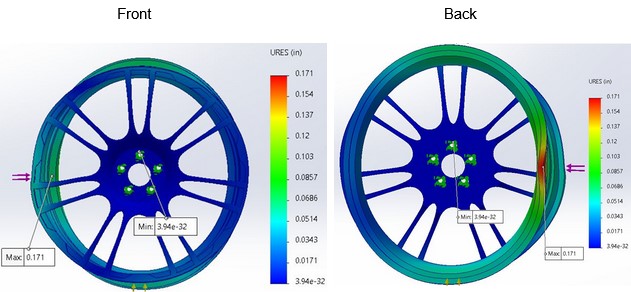

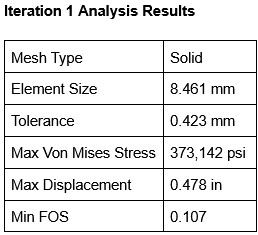

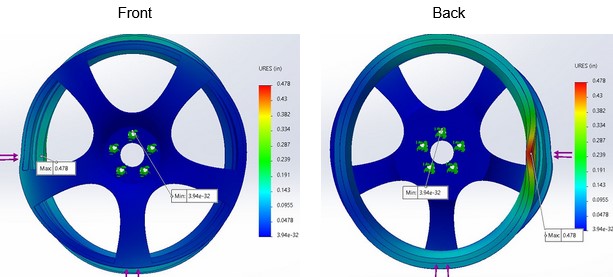

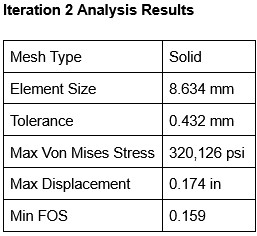

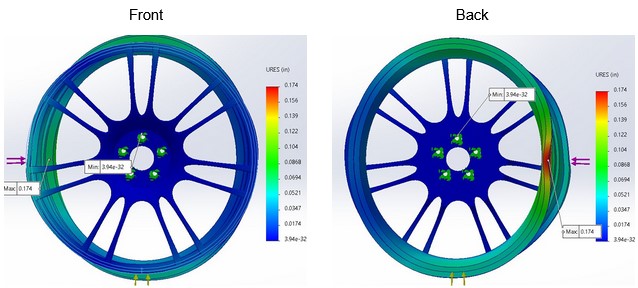

Car Wheel Optimization Project- FEA, SolidWorks (Oct. 2024)

- Conducted FEA simulations to optimize a car wheel rim for impact resistance and weight reduction.

- Evaluated 1020 Steel and 6061 Aluminum designs, optimizing for strength-to-weight ratio.

- Improved spoke geometry, achieving a 66% weight reduction (49.6 lbs to 16.8 lbs) while maintaining structural integrity.

- Reduced maximum displacement by 64% (0.478 in to 0.174 in), increasing wheel stiffness.

- Lowered maximum stress by 14% and increased Factor of Safety (FOS) from 0.107 to 0.159.

- Conducted mesh convergence analysis, ensuring results remained consistent within a <5% deviation across refinements.

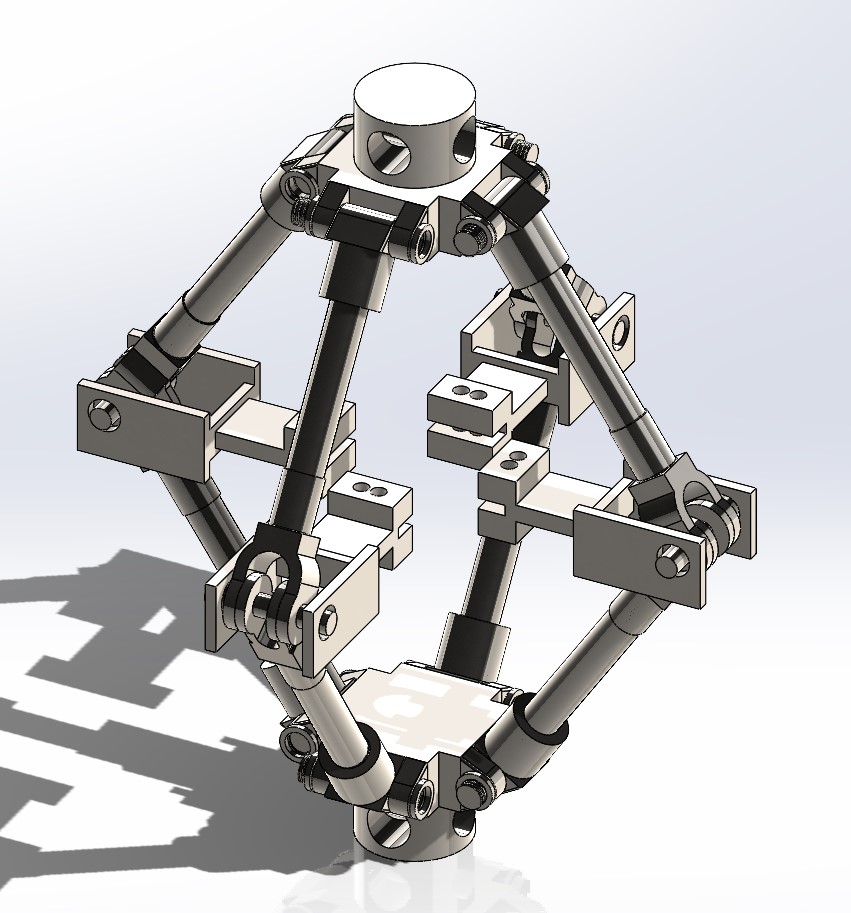

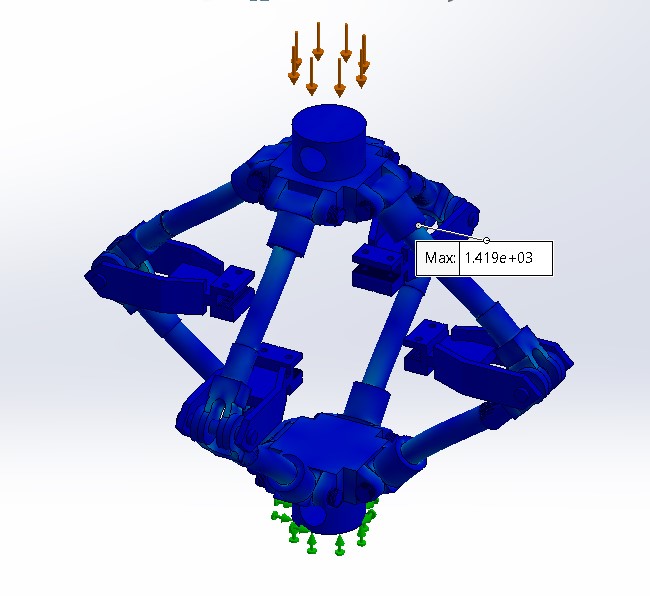

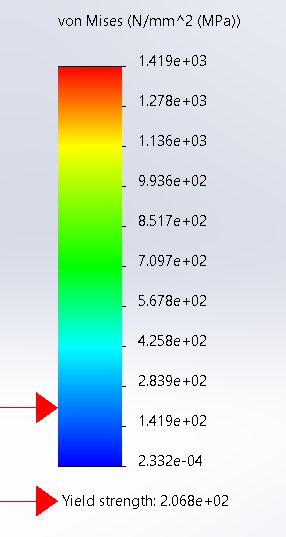

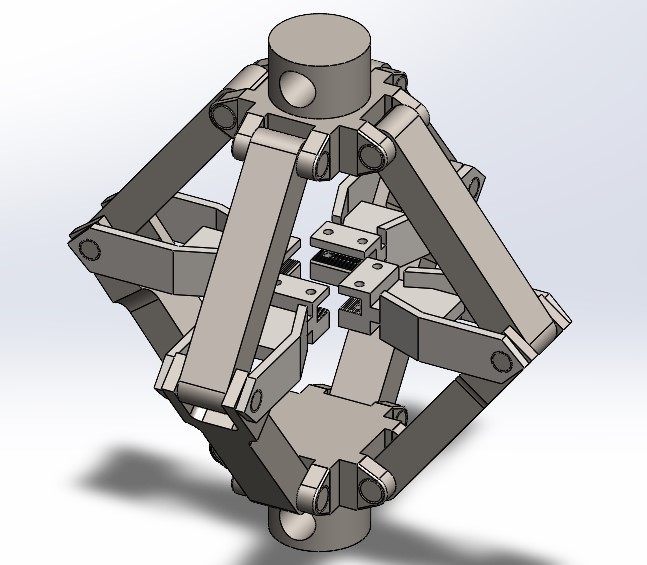

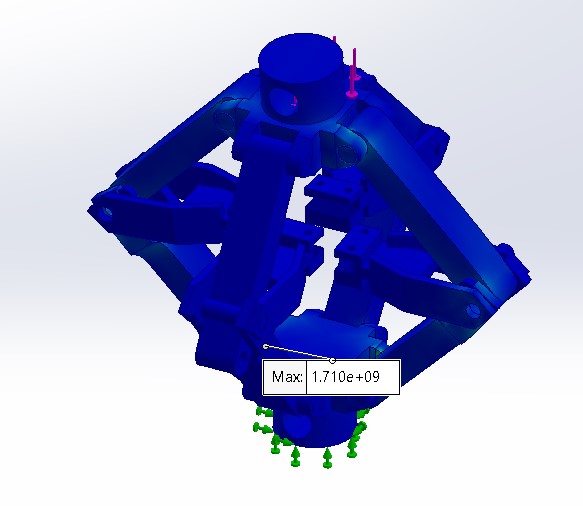

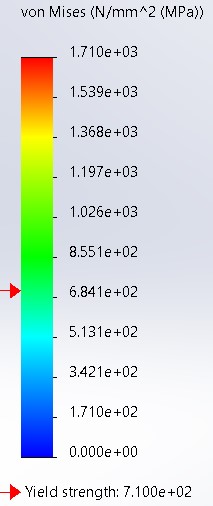

Bi-Axial Test Fixture- FEA, SolidWorks (May 2024)

- Engineered and optimized a biaxial test fixture for uniaxial testing machines, enabling multi-axis material testing

- Conducted FEA on 304 Stainless Steel, identifying failure at 1,419 MPa (Yield Strength: 206.8 MPa)

- Redesigned the fixture with AISI 4340 Steel, improving FOS from 0.15 to 0.415, but highlighting the need for further structural optimization under a 100 kN load

- Refined CAD models in SolidWorks, enhancing cross-sections, fillets, and machining considerations

- Validated design iterations through FEA, material selection, and failure analysis, demonstrating strong problem-solving in mechanical design

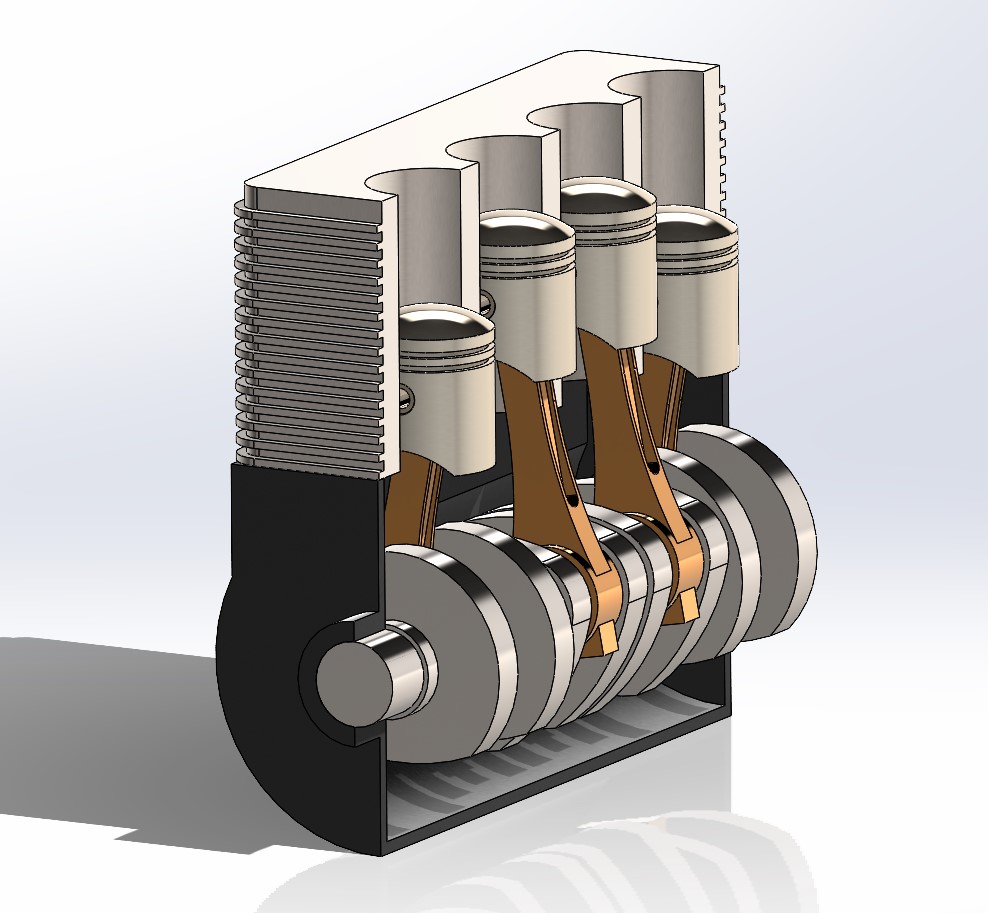

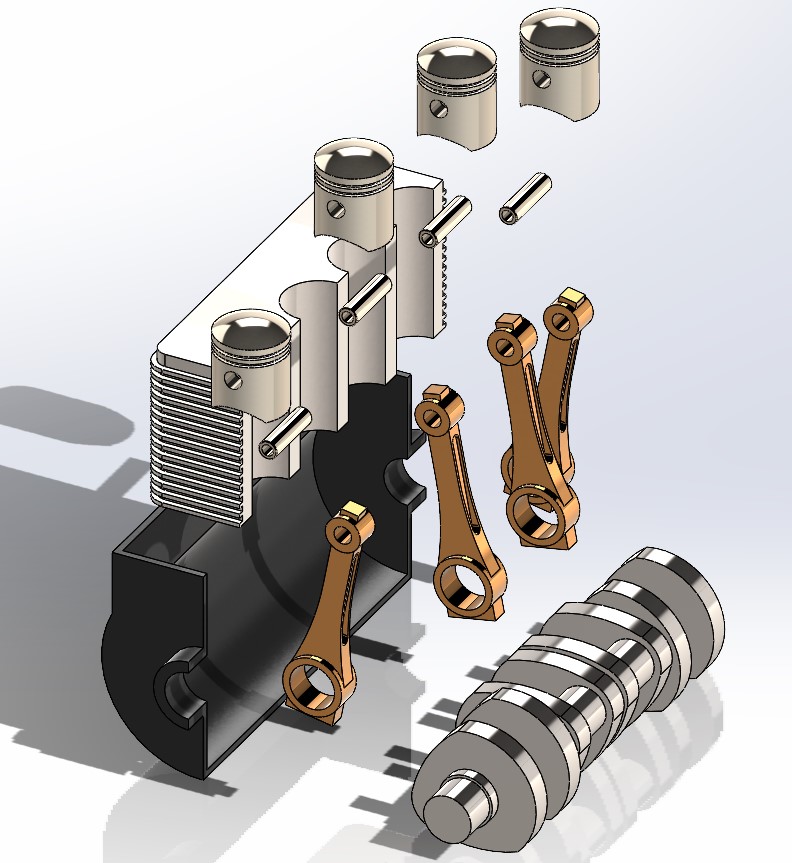

Four Cylinder Motor (Mar. 2024)

- Designed and developed a precise four-cylinder engine model using SolidWorks, demonstrating ability to create accurate mechanical simulations with proper component relationships.

- Created a highly detailed model showing optimized balance between theoretical power output, fuel efficiency, and operational smoothness in the assembly design.

- Showcased modeling expertise by accurately representing reduced rotational mass through simulated titanium and steel components, highlighting understanding of materials selection principles.

- Demonstrated comprehensive mechanical design knowledge by creating detailed models of key engine components—including connecting rods, pistons, and crankshaft—with proper alignment and fitment.

- Illustrated thorough understanding of engine mechanics through the model assembly, representing theoretical improvements in mechanical power conversion efficiency.

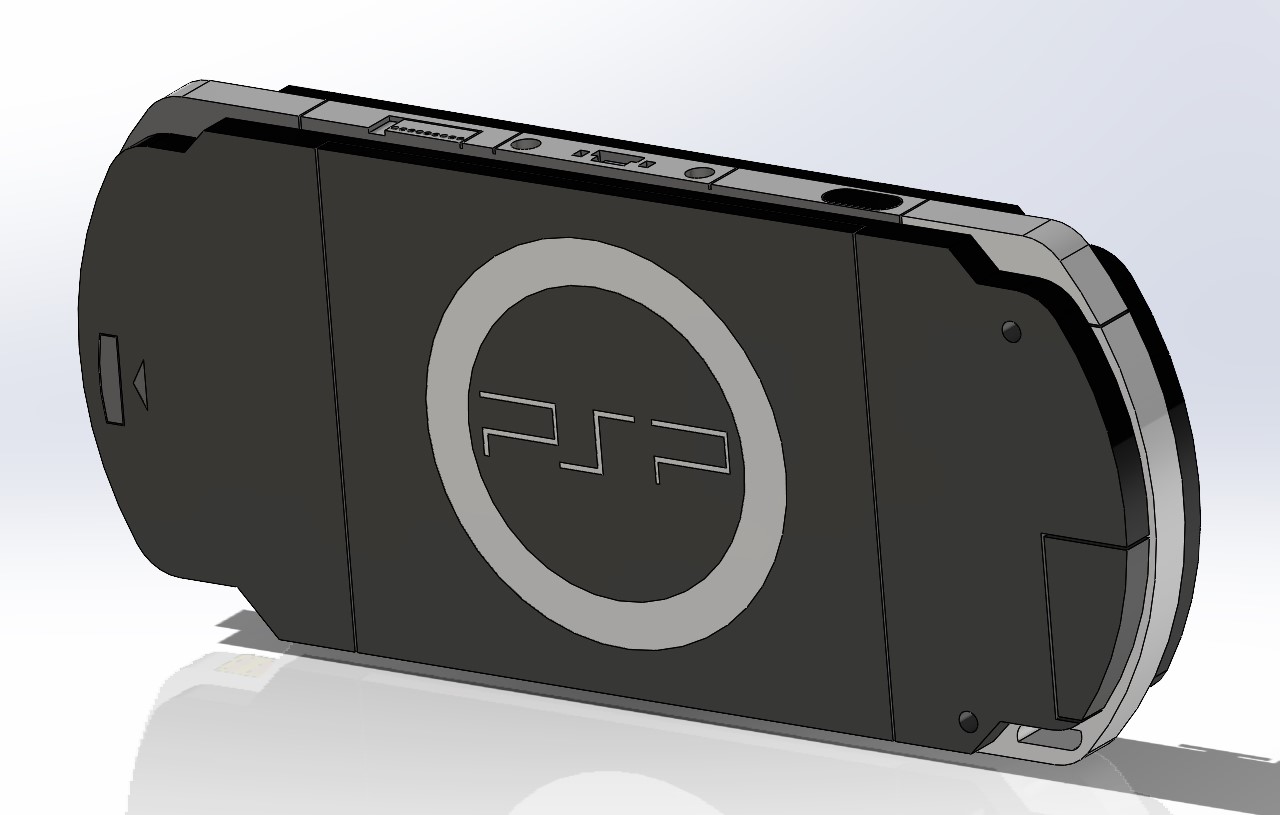

PSP 1000 (Jan. 2024)

- Created an intricate 3D model of the PlayStation Portable (PSP) 1000 using SolidWorks, capturing the device’s iconic design with 95% accuracy.

- Utilized advanced sketch tools to meticulously replicate the PSP’s ergonomic form factor, precise button layouts, UMD drive, and other critical components with high accuracy.

- Enhanced the model’s visual realism by simulating the PSP’s signature screen backlight effect, using SolidWorks appearance tools to achieve a lifelike glow.

- Demonstrated comprehensive understanding of portable gaming device engineering by integrating all key elements and features that defined the PSP 1000’s success in the market.

Technical Skills

Advanced in:

- SolidWorks (CAD, Assembly, Simulation)

- Mechanical Drafting & Design (Using SolidWorks)

- Microsoft Suite (Excel, Word, PowerPoint)

- FEA (Using SolidWorks Simulation)

- Engineering Support & Collaboration

Developing in:

- MATLAB

- Wire Harnesse Development

- ASME Standards

Certifications

Certified Solidworks Associate (CSWA): Dassault Systèmes (Feb. 27, 2025)